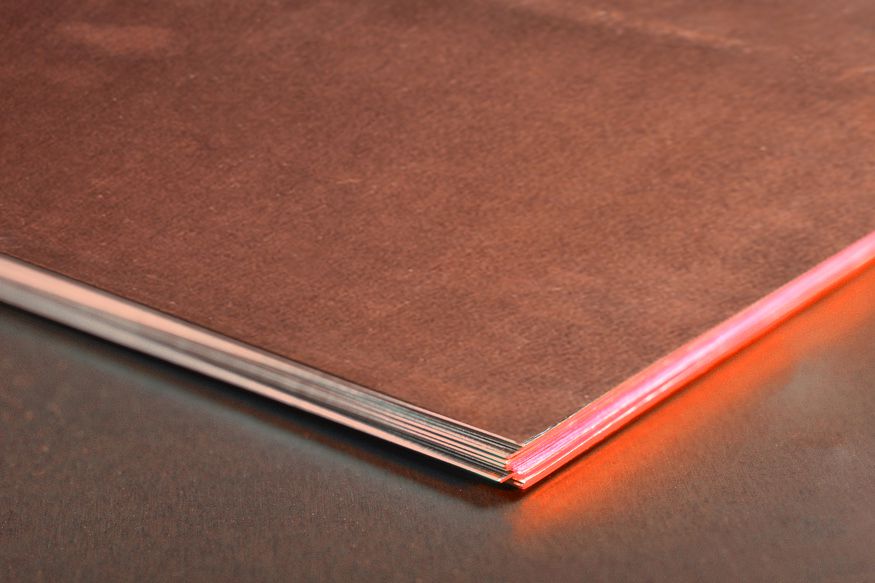

Copper Plate is made in different types. The commercially pure copper is made through electrolytic procedures. This is the reason why copper unlike most other metals could be produced up to 99.99% pure. The manufacturing processes could vary for different types. There are copper alloys as well. Nickel is one of the most used alloy material in copper components. Copper has less strength compared to other metals and cannot be used primarily for structural applications. To overcome the issue, nickel is added where the strength is increased. Copper plate types can therefore differ based on the application requirement and the addition of alloy materials. The non-pure grades of copper can contain oxygen, iron, sulfur and other elements in smaller quantities. The addition of materials differs with the different grades of the alloy. Like any other metal, copper plates are also manufactured in larger sheets to reduce manufacturing cost.

Handling is difficult with larger sheets but they are easy to manufacture and stock. When the plate dimensions are known, the Copper Sheet is then cut down to the needed dimensions and could be transported. The applications of copper could be seen in heat exchangers and boilers due to the high thermal conductivity properties. The usage of copper in electrical and electronic applications is due to its very high electric conductivity. The pure grade copper is used in electrical systems to utilize maximum conductivity. The c110 is a pure copper grade and the price of 110 copper sheet can differ from manufacturer to manufacturer.